The integrity of any construction is how well the joints and constituents are bonded together. It's vital to take care that you are using the finest methods and materials obtainable to safeguard a quality build.

Contemporary adhesives are more powerful and are an increasingly popular substitute for nails and bolts that will make the job easier and faster, not to mention your physique will be durable. Because of growing technology adhesives are intended for specific building purposes. These are some of the benefits of adhesives in construction.

Aids of Adhesives in Construction

There is absolutely no question that fasteners have their place in the construction sector. There are improved options that can be used as a substitute or in combination with fasteners. Adhesives have significant advantages regarding strength and durability, like:

• Offer an augmented load-bearing maximum weight through the whole surface

• The aptitude to bond two different materials together

• Will not rust like nuts and bolts of metal

• Enhances added strength to the bond since it covers the whole surface endways

• The capability to captivate more energy short of cracking under stress

• Make the material less susceptible to variations in temperature

• Increase in lasting sturdiness

• Better sealing properties owing to the incessant contact between two materials.

• The capability to seal small gaps if there is a need to do so.

• Better-quality thermal and electric insulation and conductivity.

Additional Considerations for Adhesives

It is significant that engineers still cautiously plan the purposes of construction adhesives. Joint designs, preparation needs, and curing endorsements should be considered before applying adhesives in construction. Also, there are numerous adhesives obtainable precisely custom-made to numerous construction materials. The correct one for your construction will depend on the kinds of materials that you are bonding.

Taking the Baton from Fasteners

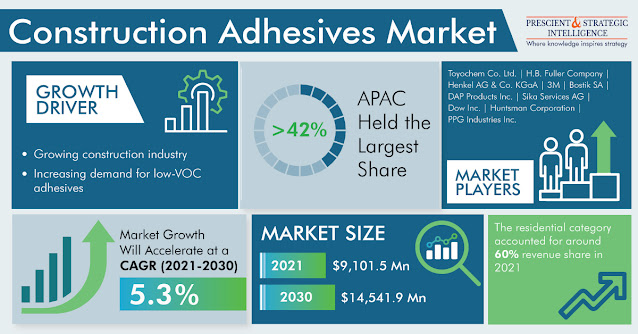

Fasteners have ruled the roost in the past in the construction industry in the past, but, when it is about the new-age bonding between construction materials, construction adhesives are surely the answer. Because of the adhesives’ upper hand, the demand for the same is boosting with every passing day, and the construction adhesive industry will reach the value of about 14,542 million by the year 2030.

With an increase in construction around the world, the adhesives used in this industry have begun to take ascendance.